Electrical Gloves

Rubber insulating gloves are personal protective equipment (PPE) used in carrying out work with energized parts, and are mainly used by lineman involved in the maintenance of power supply lines. They form the first line of defense in the utilities, telecommunication and transportation industries, in particular, the electric powered trains, hybrid automobiles and even Formula 1 racing circuits since the introduction of kinetic energy recovery system (KERS).

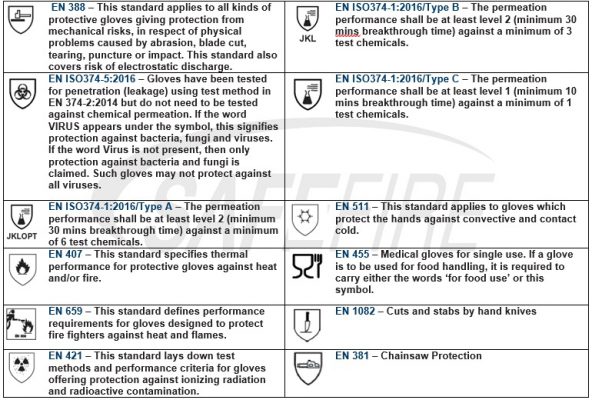

Your guide to safety standards and choosing the right hand protection:

European Standards

Implies that the gloves comply with the basic requirements laid down by the EC Regulation: Personal Protective Equipment.

Simple Design (Category I)

For areas of ‘minimal risk’ where the effects of not wearing a glove are easily reversible or superficial. Such products are self-certified.

Intermediate Design (Category II)

For areas of specific risk i.e. mechanical risks. Such products will have been EC type tested against European test methods and certified by a notified body.

Complex Design (Category III)

For areas/applications that can seriously or irreversibly harm the health. Such products, in addition to the CE type test, will also have to be either produced under an approved quality system OR be type tested on an annual basis

Related products

Safety

Breathing Apparatus

Breathing Air Compressors

Breathing Air Compressors

Breathing Air Compressors

Safety

Anti-Skid Protection & Flooring

Arc Flash